PRODUCTS

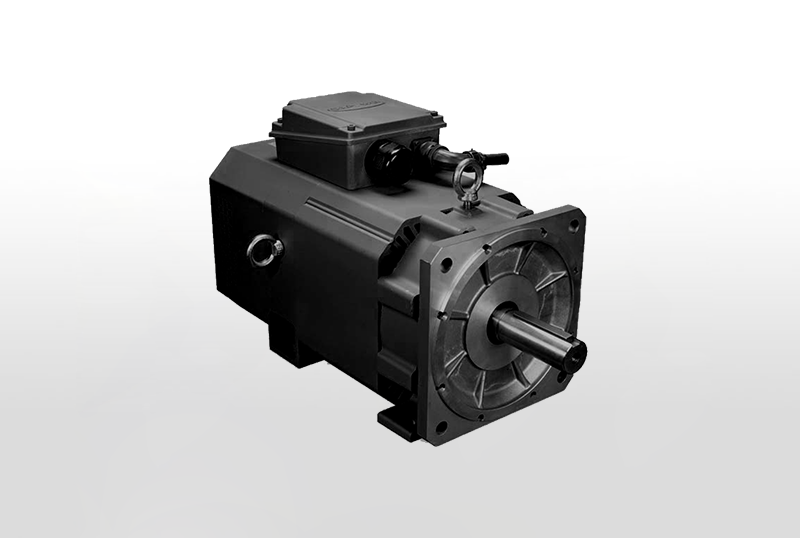

AC Synchronous Servo Motor

Features

- Motor Frame----Precise and rigorous structure design, improving accuracy and extending motor’s lifetime.

- Dynamic Equilibrium----All processing and units are analyzed and corrected with dynamic equilibrium.

- Precision Bearing----We only adopt precision grade bearings to ensure high-speed motor operation and prolong lifetime.

- Cooling System----Using independent forced cooling system to maintain servo motor in good cooling effect no matter in full speed or idle.

- High Reliable Encoder----With protection web to ensure no signal interference, so improving the reliability of close-loop.

FEATURES

- If above base frequency, stable HP and wide-range power output during high-speed operation.

- If below base frequency, keeps linear stationary magnetic field during low-speed operation, to maintain constant torque output.

- Special routing design and insulation degree that make foil insulation intact when driver is operating loading wave servo control.

- Adopting only high-end silicon steel to ensure motor maintains superior servo characteristic in linear control in operation range.

- Special magnetic design and analysis, makes sure there is no magnetic saturation in operation range and dramatically upgrade motor’s servo characteristic and reduce the damage to motor and driver caused by inrush current.

- Servo motor in quite high power to volume ration due to adopting advanced precision design model.

- Better rotational inertia design to achieve higher response characteristic when motor performs rigid tapping.

- Precision stator and rotor slot design, ensuring motor operation smooth and fast during positioning control without any bounding situation caused by pulse magnetic field.

HOT PRODUCTS

-

NEWS

-

2024 Taipeiplas

2024/09/24 -

2018 NPE

2018/05/01 -

2018 CHINAPLAS

2018/04/09

-